CORRECT LOAD DISTRIBUTION

Correct Load Distribution in Logistics: Distributing Weight Evenly in Vehicles and Shipments

By S. Ashoka Heavy Lifterers & Consultants

In the logistics and transportation industry, correct load distribution is one of the most critical aspects of ensuring safe, efficient, and compliant operations. Whether goods are being transported by road, rail, air, or sea, the even and proper distribution of weight within vehicles or containers plays a vital role in maintaining safety, vehicle performance, fuel efficiency, and adherence to legal standards.

According to S. Ashoka, a logistics expert, “An imbalanced load is not just a risk to goods, but a risk to life.”

Importance of Load Distribution

Proper load distribution is crucial for vehicle stability and steering control. An unevenly loaded vehicle can tilt, sway, or even tip over during sudden maneuvers or braking. For trucks, trailers, or ships, overloading one section can cause mechanical strain, suspension damage, or tire blowouts.

As S. Ashoka explains, “Placing too much weight at the rear of a truck may lift the front axle, severely affecting its braking and steering capability.”

Emergency Response Planning for Crane & Hydra Operations

1. Pre-Emergency Risk Assessment

- Identification of potential hazards (e.g., overload, equipment failure, unstable ground).

- Site-specific risk mitigation planning.

2. Emergency Response Protocols

- Clear communication channels for reporting incidents.

- Defined roles & responsibilities for crane operators, riggers, & safety personals.

3. Training & Drills

- Regular emergency evacuation drills involving all crew.

- Specialized training in equipment shutdown, load release, & first aid.

4. Backup & Recovery Plans

- Availability of standby equipment (hydras, jacks, fire extinguishers).

- Coordination with local emergency services.

5. Emergency Contact Systems

- On-site and off-site emergency contacts posted and accessible.

- Use of radio, alarms, and mobile alerts to ensure fast response.

Safety First in Crane Services

The S Ashoka Way : At S Ashoka Heavy Lifts & Consultants, safety is not just a rule—it’s a commitment. Every crane operation we handle is carried out with strict safety measures to protect people, equipment, and the environment. Cranes are powerful tools, but without proper planning and care, they can become dangerous.

That’s why we begin every job with a detailed site inspection to identify risks like uneven ground, overhead power lines, or nearby structures. Our operators are fully trained and experienced, and they always follow the crane load chart to make sure we stay within safe lifting limits.

We believe in clear communication on-site—using radios, hand signals, and daily safety meetings. Our team wears all required safety gear, including helmets, gloves, and high-visibility jackets.

At S Ashoka, every project is done with 100% focus on safety, no matter the size or complexity. Because for us, a successful lift is a safe lift.

Let’s work smart, lift strong, and stay safe—the S Ashoka way!

Best Practices for Load Distribution

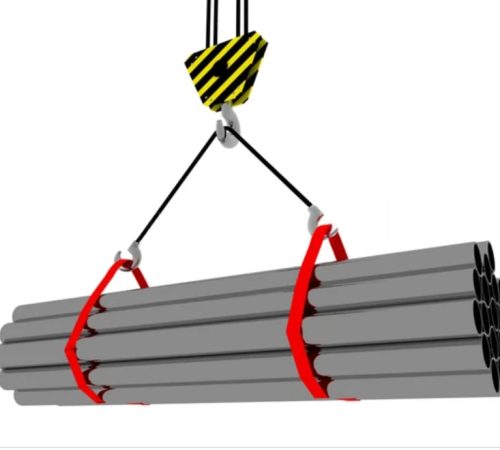

Load Chart: This is the most critical document. Every S. Ashoka crane comes with a load chart that specifies the maximum lifting capacity for different radii (distance from the crane’s center of rotation to the center of the hook), boom lengths, and configurations (e.g., with or without jibs, outrigger spread).

Gross Load: This is the total weight being lifted, including the actual material, the rigging gear (slings, shackles, spreader bars), and the hook block.

Ground Bearing Pressure (GBP): The force exerted by the crane’s outriggers or tires onto the ground. Exceeding the ground’s capacity can lead to subsidence, tipping, or structural failure.

Outrigger Spread: The distance between the outrigger pads. Maximizing the spread provides the largest base of support and best stability.

Cribbing/Matting: Material placed under outrigger pads to distribute the load over a larger ground area and prevent the pads from sinking into soft ground.

II. Pre-Lift Planning & Site Assessment (Crucial for S. Ashoka Cranes)

Before even deploying an S. Ashoka crane, thorough planning is essential:

Site Survey:

Ground Conditions: Assess the soil type (e.g., clay, sand, gravel), its compaction, and any hidden voids, underground utilities (pipes, cables), or basements. This directly impacts the required cribbing.

Slope: Identify any slopes. Cranes should ideally operate on level ground. If not possible, the load chart might need to be de-rated, or specific leveling procedures must be followed.

Obstructions: Note overhead power lines, buildings, trees, or other structures that could interfere with the boom or load.

Access/Egress: Plan the route for the crane and load to ensure safe movement.

Load Calculation:

Accurately determine the gross load. This includes the material, rigging hardware, and the crane’s own hook block.

Never estimate the weight. Use manifest, drawings, or weigh the load if possible.

Crane Selection & Configuration:

Select the appropriate S. Ashoka crane model based on the calculated gross load, required lift height, and radius.

Consult the load chart to determine the correct boom length, jib configuration (if applicable), and outrigger spread for the specific lift.

Ensure the crane has sufficient counterweights for the planned lift.

Outrigger Planning:

Determine the maximum anticipated ground bearing pressure at each outrigger based on the load chart and lift scenario.

Calculate the required size and thickness of the cribbing/mats to distribute this pressure over an area that the ground can safely support. A common rule of thumb is to reduce the pressure to less than the ground’s safe bearing capacity.

Smart Load Management

The Future of Crane Services

In the world of heavy lifting, precision and safety are non-negotiable. That’s why technology in load management is becoming a game-changer for companies like S Ashoka Heavy Lifts & Consultants.

Modern load management systems help monitor, control, and balance crane loads with pinpoint accuracy. Smart sensors installed on cranes now provide real-time data on load weight, angle, and distribution—minimizing risks of overloading and imbalance.

With the help of automated load charts and digital simulations, lifting plans are created with greater precision. These tools adjust for changing conditions like boom length and radius, ensuring safer and optimized lifts.

AI and analytics further enhance performance by predicting risks and suggesting preventive measures before issues arise.

At S Ashoka, we blend cutting-edge load management tools with our vast field expertise to ensure each lift is executed with maximum safety and efficiency.

Whether it’s a turnaround shutdown or a critical heavy-lift job, our smart approach to load management guarantees zero compromise on safety and performance